Pigment Red 208

Pigment Red 208

CAS: 31778-10-6

Molecular Formula: C29H25N5O5

Pigment Red 208 - Names and Identifiers

Pigment Red 208 - Physico-chemical Properties

| Molecular Formula | C29H25N5O5 |

| Molar Mass | 523.54 |

| Density | 1.39±0.1 g/cm3(Predicted) |

| Boling Point | 632.0±55.0 °C(Predicted) |

| Flash Point | 336°C |

| Water Solubility | 3.2μg/L at 24℃ |

| Vapor Presure | 1.44E-16mmHg at 25°C |

| pKa | 11.41±0.30(Predicted) |

| Refractive Index | 1.691 |

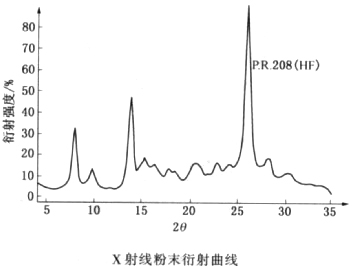

| Physical and Chemical Properties | hue or color: bright red density/(g/cm3):1.42 Bulk density/(lb/gal):11.2-11.6 melting point/℃:>300 average particle size/μm:50 particle shape: Cube specific surface area/(m2/g):50;65 pH value/(10% slurry):6.5 oil absorption/(g/100g):86 hiding power: transparent type diffraction curve:  reflection curve:  bright red powder. Light resistance 6~7. Resistance to organic solvents can reach 4~5, acid resistance, excellent alkaline, no migration phenomenon. |

| Use | The pigment gives a neutral red color with a hue of 17.9 degrees (1/3SD,HDPE) and has excellent solvent resistance and chemical resistance properties. Mainly used for plastic pulp coloring and packaging printing ink, no migration in soft PVC, light-resistant Grade 6-7(1/3SD), heat-resistant 200 ℃, and C.I. Pigment yellow 83 or carbon black mosaic Brown; Used for polyacrylonitrile puree coloring, natural color light resistance is grade 7; Used for acetate fiber and polyurethane foam puree coloring; Can also be used for packaging ink, its solvent resistance, sterilization treatment performance is good, but because of the light resistance, weather fastness limits the use of a large number of common coatings. mainly used for plastic coloring. |

Pigment Red 208 - Reference Information

| LogP | 1.41 at 24℃ |

| EPA chemical information | Information provided by: ofmpub.epa.gov (external link) |

| usage | is mainly used for plastic coloring. |

| production method | reaction equation operation process uqf 9. 7 parts of butyl o-aminobenzoate, 100 parts of 2mol/L hydrochloric acid and 100 parts of water were stirred and dissolved, cooled to 6 ℃, and 25 parts of 2mol/L sodium nitrite solution were added in the next time under rapid stirring, stirred, filtered, and adjusted pH = 5 for coupling. 19 parts (84%) of 5-(2 '-hydroxy -3'-benzamido)-benzimidazole -2-one and 75 parts of 2mol/L-sodium hydroxide solution, 300 parts of water are stirred and heated to 60-65 ℃ for hot filtration to remove insoluble substances, cooled to below 10 ℃ and then dropped into the above diazo solution, controlled pH = 5-6.2, stirred for 1h after coupling, and heated to boiling, hot filtration, water washing, dry 20 parts of crude pigment. |

Last Update:2024-04-09 19:05:09